Meeting venue: Komai Clinic Project Conference Room

Time: 9:30 am, November 26, 2022

Participants: Shao Bing, Wang Song, Xie Chunhua, Song Jianwei, Han Jian, Dang Jun, Wang Lixin, Lu Xiaoqin, Liu Suwen, Ding Shijun, Hu Qiguang, Sun Zhisheng, Cheng Jinbao, Yang Le, Chen Xuantao, Zhou Weijian, Jin Yongchang, Zhang Su, Chen Yuan, Song Shuang, Wu Wei, Yu Hongtao, Huang Yu, Xie Xinmin, Fang Weijiang, Shen Wei

Brief meeting content:

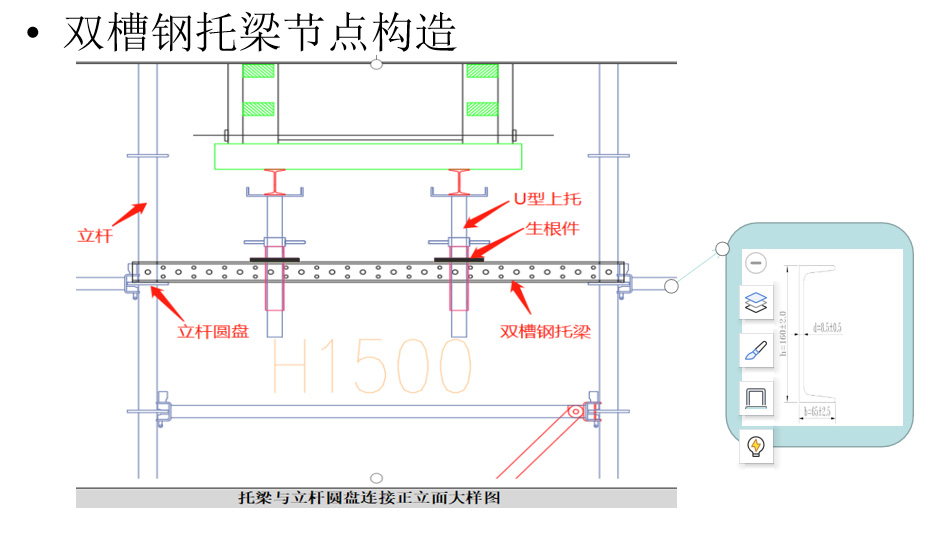

At present, the construction projects are gradually promoting the die support system of the buckle frame and the erection of the protective frame, the erection technology and scheme are not mature enough, and the actual application process needs to be continuously improved and summarized according to the characteristics of the project. In order to improve the cognition of the tray support mold system of the company's on-site special supervisor and director, the Chief Engineering Office and the Engineering Department organized to learn and exchange the key construction points of the tray support mold system, the construction technology of the super long tray buckle top support, the construction of the tray buckle high support mold, and other key business knowledge of supervision and monitoring. Through this study and exchange, the supervision engineers generally have a field control and standard and practical perception of the construction of the tray buckle, and take out the shortcomings of the construction of the winch buckle of the project they are responsible for to discuss together, optimize the construction plan and matters for attention during acceptance, and consolidate and improve the business knowledge of the supervision engineers attending the meeting.

1. Director Feng Saijun introduced the project overview, organized the participants to enter the site of Kemei diagnosis project admission training, so that the management of construction should be safe, and the management of safety should know safety;

2. Wang Zun, professional supervision engineer of Kemei Diagnostic Project, and Feng Saijun, director of the project, introduced each construction step, precautions, logical sequence, key points of supervision and monitoring, safety risk management and control, and key contents of data document collection during the construction of the project's tray frame;

3. After explaining the theoretical knowledge of the plan and daily control, the director of the project department led the colleagues who came to visit and exchange to introduce the on-site physical objects and on-site safety management experience;

4. Jointly discuss the calculation and analysis of the force effect of the application technology of the super long top bracket with double support channel steel beam;

5. The tray buckle frame with long top bracket and double support channel steel beam support mold system is dismantled and the concrete molding is visited.

中文

中文 English

English